Good Design Deliver Intelligent Motion Solution

BLDC motor drive technology is integrating the BLDC motor and drive into a single

package to simplify the system, minimize interconnection cabling, reduce noise and

solve motor-drive compatibility issues. With good design of BLDC drivers are capable of

power management, network connection, accurate position sensing and real-time

condition monitoring.

- MICRO BLDC MOTOR

- POWER TOOL MOTOR

- VARIABLE SPEED MOTOR

- HUB MOTOR

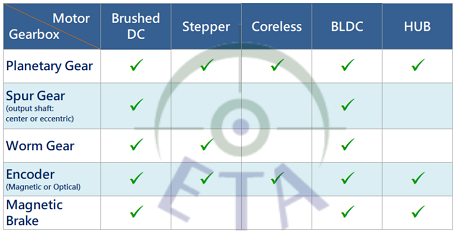

*Optional Components : Gearbox, Encoder, Magnetic Brake, UL Cable Assembly.